Precision Finishing With Diamond Lapping Compounds

A good quality grinding wheel on a rigid machine can produce a surface with a roughness around 0.25 microns Ra. In some applications this isn't enough; in others flatness is of greater importance than finish. In either situation the next step is to move on to lapping.

PRECISION FINISHING

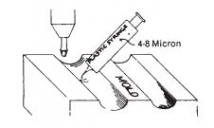

In lapping an abrasive compound, composed of abrasive particles in a liquid or paste transport medium, is placed between the work piece and a lapping plate. Movement of the plate rolls the particles across the surface, removing raised peaks and flattening high regions. Depending on the work piece material, roughness numbers of under 0.30 microns Ra are achievable.

Other reasons for lapping are to bring something down to a precise and uniform final size and to produce a very flat surface. (Think of flatness as the rolling of hills and valleys, while roughness is the furrows plowed in the field.) Lapping doesn't put any stress or heat into the surface, and the low cutting forces make it a distortion-free way of finishing thin-wall parts.

LAPPING WITH DIAMOND COMPOUNDS

A number of abrasives can be used but diamond has several advantages:

highest material removal rates, by virtue of it's exceptional hardness

excellent surface finish, because the edges cut cleanly and diamond can be graded down to micron-level. (Producing a uniform, scratch-free surface demands particles of the same size: any that are larger will produce undesirable scratches.)

When lapping, standard practice is to use a cast iron lapping plate. For lapping with superabrasives (diamond or CBN) though it's recommended to use a composite metal plate such as tin, copper or cast iron.

The transport medium used in a diamond lapping compound can be either oil or water soluble. Oil soluble compounds are the most common and can be used on ceramics, carbides, cast iron and other metal surfaces.

A water soluble compound is used when the work piece is sensitive to oil. It's often employed for finishing electronic and electro-optical components and is widely used for magnetic read/write heads and semiconductor applications.

Companies like CDT supply precisely graded diamond lapping compound in syringes for easy dispensing. The coarsest grades, in the region of 40 to 90 microns, gives rapid stock removal while smaller particle sizes are used for finishing. To give one example, an application like preparing metallographic samples needs abrasives of less than two microns in size.

CHOOSE YOUR DIAMONDS CAREFULLY

In many applications the finish resulting from grinding is good enough. When it isn't, the next step is lapping. As with grinding, diamond makes an excellent abrasive, but for best results needs to be selected and used appropriately.